WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Not «breath-» but wireless

October 9, 2025

Bluepath Robotics, an internal innovation project at the Ford subsidiary Otosan, which was spun off at the end of 2023, develops and produces autonomous mobile robots for a wide range of intralogistics applications. Now, Wiferion enables the inductive power supply of the AMRs.

Electric monorail system for Quark & Co

October 9, 2025

NÖM produces a wide range of dairy products, yogurt, butter, and curd cheese from approximately 450 million kg of milk from 2,200 farmers in the region build a fully automated shipping warehouse with comprehensive conveyor technology for 26,000 pallet spaces.

The fire is left without air

October 8, 2025

The fire protection specialists of the Wagner Group have been honored with the "GIT Safety Award 2026" for their "OxyReduct F-Line." The system expands the OxyReduct process with H2- based fuel cell technology, which simultaneously ensures emission-free energy supply.

Temperature-controlled at the motorway junction

October 7, 2025

Movianto, a logistics service provider specializing in pharmaceuticals and healthcare, is setting up a new cold storage facility in Wiesloch-Walldorf this month. A photovoltaic system there produces approximately 3,100 MWh per year, more electricity than the site consumes.

Fusion reactor in creep mode

October 7, 2025

Despite all the political turmoil currently shaking the world, work on the ITER fusion reactor, in which countless nations are involved, continues – much like on the ISS. Recently, another of the 15-meter-high segments for the future plasma chamber was delivered by heavy-duty transport.

Nonstop strapping

October 6, 2025

Mosca offers a comprehensive portfolio of integrated end-of-line systems for transport packaging, strapping machines, stretch wrappers, and associated consumables. Strapping made from materials such as PP and PET is produced with increasing recycled content.

Dynamic open-plan area

October 6, 2025

Relocations often involve considerable effort. Furniture needs to be transported, boxes packed, and unwanted items disposed of. The company " Optimal Umzug " from Lachen, Canton of Schwyz, offers services tailored to the greater Zurich area.

Optio L-Series updated

October 6, 2025

Developed with the user in mind, the completely redesigned generation of low-level order pickers in the Optio L series from TMHE sets new standards. Increased platform lifting heights, low entry, and versatile model variants for loads up to 2.5 t make these devices highly sought-after helpers.

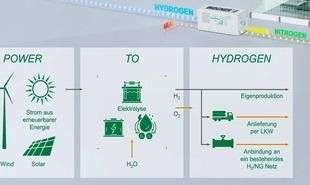

Cold chain in transition: Ambitious goals

October 2, 2025

Temperature-controlled logistics is facing an energy revolution: battery-electric trucks, long-range hydrogen vehicles, and cryogenic cooling with nitrogen are transforming the industry. Enough "material" for the SVTL to discuss future processes and alternatives at Galliker in Altishofen.

DLR expands drone defense

October 2, 2025

While Russian drones have long been surveying German bases and critical infrastructures as potential targets for their “ asymmetric warfare ” a project called CUSTODIAN (Counter-UAS Technologies for Detection, Interception and Neutralization) is now slowly gaining momentum at the DLR.

Run along – or drive ahead?

WAGNER Switzerland AG

Run along – or drive ahead?

June 23, 2022

behind Linde MH's World of Material Handling is that visitors by the exhibitor booth for a quick visit . Whether it's sunny or cloudy, they experience realistic applications firsthand. " Indoor" at the N20 in Mannheim will be all about the question: Which mode should I choose?

Short walking and driving distances increase process efficiency in order picking. Logistics service providers and retail chains can now fully exploit this optimization potential with the semi-automated Linde N20 SA and N20 C SA order pickers. The new semi-automated option offers two driving modes in which the trucks automatically follow or drive ahead of the operator. The result: employees are relieved of non-value-added activities. Picking performance is said to increase by up to 20 percent.

Picking is labor-intensive and requires stamina and attention from warehouse employees. A significant portion of the process involves walking between the shelf and the picking device. This activity, unlike picking goods from the shelf and placing them on the load carrier, does not add value. Even a few seconds in each handling operation add up to significant time losses over the course of a workday. "Even a few steps, repeatedly walked, fatigue the operator and rob them of energy that could be better used for error-free completion of the picking process," points out Philipp Stephan, Product Manager Automation & Intralogistics Solutions.

Detour to IT

Detour to IT

At the same time, picking rates must be increased, error rates reduced, and health impairments prevented. The picking process therefore offers great potential for increasing the overall efficiency of warehouse logistics – optimization potential that is now being tapped with the SA option for Linde order pickers with load capacities of up to 2.5 t. Both driving modes aim to significantly shorten travel and walking distances during order picking in the aisle. At the same time, the tiring process of getting in and out of the truck is eliminated, reducing the risk of accidents. This has positive effects on throughput and productivity in the warehouse.

One of the most common processes in high-bay warehouses is picking from one side of the rack, where an employee walks along the rack aisle in a U-shaped pattern. This activity supports the semi-automatic "follow-me" function. If the person stops, the truck also stops, allowing them to place the goods directly from the rack onto the pallet. If the operator continues walking, the truck continues its journey. The staff moves along the rack and collects the goods without having to constantly walk to the driver's workstation and back. The onward journey is triggered when the employee passes a specific point on the truck and thus passes through the so-called "virtual wall."

Photos: wl

Photos: wl

If the vehicle needs to be loaded from both sides, the "stop-and-go" function is ideal. The vehicle moves along the center of the aisle at a constant speed and is directed forward by a remote control, ideally worn on the operator's belt. The operator walks behind the vehicle back and forth between the rack sides to pick up or place goods – a method preferred in smaller warehouses. Another advantage here: there's no need to walk back to the operator station, nor is there any need to get in and out.

Both functions are based on ultra-wideband wireless technology and can be adjusted to within a centimeter. At the end of the aisle, the vehicle stops automatically to avoid collisions with other vehicles. By entering, the operator ends the semi-automatic mode and manually moves the vehicle to the next aisle. Since one of the biggest concerns about automated vehicles is safety, the N20 SA and N20 C SA order pickers are equipped with a high-performance safety scanner that detects people and other industrial trucks. The scanner, mounted low on the chassis, also detects unexpected obstacles. To prevent damage to shelves and give the operator sufficient space for their work, the vehicle maintains a minimum distance of 50 centimeters from the shelves, but can also be positioned at a greater distance at the beginning of the aisle. Most of the functions are already familiar from the comparable vehicle type from the Hamburg-based sister company under the Kion umbrella – but are nevertheless characterized by high efficiency in ongoing operation.

www.linde-mh.de