WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Staffing needs almost halved

November 27, 2025

The US cooperative Associated Wholesale Grocers keeps 54,600 dry goods, fresh produce, and frozen food items in stock for its 1,100 members using a highly automated, full-range logistics center . The facility is designed for a daily picking capacity of more than 460,000 retail units.

Knowledge transfer in the Seychelles

November 26, 2025

Natural hazards are increasingly occurring worldwide in the form of floods, landslides, forest fires, storms, earthquakes, and rockfalls. Acute crisis management is required, but so are long-term strategies for transportation routes, where Gasser Felstechnik provides assistance in the Seychelles.

German Design Award for Traigo-i

November 26, 2025

Following the Red Dot Design Award 2025, Toyota Material Handling's new 48-volt counterbalance forklift, Traigo_i, has now also received the German Design Award 2026 in the Excellent Product Design – Industry category. The focus: the complete integration of lithium-ion technology.

Long-term contracts at SBB Cargo

November 25, 2025

Numerous SBB Cargo Switzerland transport customers, such as Migros, have signed new single wagonload (EWLV) contracts with terms of up to ten years. New contracts have also reportedly been concluded with fenaco, Stahl Gerlafingen, and the Swiss saltworks.

Cooperation with Capra Robotics

November 25, 2025

Frei Fördertechnik announces its future collaboration with the Danish robotics specialist Capra. "This expands our portfolio to include mobile robot platforms that bring even greater flexibility and efficiency to production and logistics," says Michael Schüpbach, Head of Automation & Robotics. The AMRs are versatile and can be used in a wide range of applications.

SSI subsidiary continues to consistently rely on SAP

November 25, 2025

Since 2021, the software specialists at SWAN have been part of the SSI Schäfer Group, responsible for the SAP projects of the globally active intralogistics experts and supporting companies in implementing future-proof solutions – from highly automated distribution centers to integrated production logistics. The course is right.

Arne Sturm will be the new CEO in Hirschthal

November 25, 2025

Jungheinrich Switzerland will have a new managing director as of January 1, 2026. Arne Sturm will succeed Martin Weber, who is leaving the company after 18 years – eleven of them as managing director – at his own request to pursue new topics and challenges.

Another 50 million for new TGW headquarters

November 24, 2025

TGW Logistics is currently investing €100 million in expanding its production capacity at its headquarters in Austria. Now, with an expansion of the existing office building at the site, a five-story office building with 14,000 m² of usable space is being constructed for around €50 million, with completion expected by the second half of 2028.

AutoStore for Belgian hospitals

November 22, 2025

AutoStore system for Maria Middelares, a non-profit medical organization in Belgium, and Aalter in East Flanders, about 60 km west of Brussels.

Reliable data instead of empty phrases.

November 21, 2025

The Basel Logistics Cluster of the Basel Chamber of Commerce (HKBB), together with the cantons of Basel-Stadt and Basel-Landschaft, industry associations, and infrastructure operators, has published a guide to sustainable logistics in the Basel region. Supply chain expert Daniel Bubendorf explains why such a guide is needed.

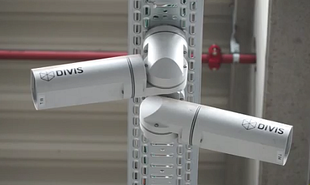

No more blind spots

WAGNER Switzerland AG

No more blind spots

January 20, 2021

All shipments can be tracked fully automatically and at the individual package level via video. A complete solution involved installing 134 cameras at trans-o-flex's premises at the new distribution center in Hamm. 98 of these are located indoors. The works council was involved in every step of the process.

The facility, built on a 33,000 square meter plot, opened on schedule in May 2020 and is setting new standards for the company. This also applies to the fastest possible resolution of shipment disruptions, which can occur from time to time given the approximately 40,000 parcels and 900 pallets handled daily in the pickup and delivery area. The company invested in a video management system from Divis .

In addition to parcels, trans-o-flex also transports pallets, which are handled together in a hall in Hamm. To be able to visually track both types of shipments with a single video solution, Divis supplemented the ParcelVIS system, developed for parcels, with functions from the CargoVIS solution designed for palletized shipments.

Photos: DIVIS

Photos: DIVIS

One of the project's particular challenges was a very tight schedule. This was further complicated by the fact that some suppliers were struggling with scheduling problems due to the COVID-19 pandemic. Finally, the strictest hygiene regulations had to be observed throughout the entire project.

The sorting system automatically directs packages from six receiving stations to one of 119 loading bays for trucks or vans. Along the way, the shipments are automatically scanned, measured, and weighed. Because the sorting belts run more than four meters above the warehouse floor, pallet-loaded forklifts can drive underneath them.

In addition to conventional cameras, panoramic cameras were also installed, based on the 360° concept developed by Divis. These cameras allow for a 360° all-around view, enabling comprehensive tracking of shipments, while eliminating the blind spot below the camera typical of standard cameras. A single panoramic camera, it is said, covers large areas and can replace up to four conventional cameras, thus minimizing cabling and energy costs.

Recording takes place at a frame rate of at least 8 frames per second (fps), which are stored on two recorders, each with a capacity of 96 terabytes. Thanks to the 4K resolution, even the smallest details can be zoomed in on in high quality. By entering the package number, ParcelVIS can locate any package in seconds and track its path through the sorting system. "All loading and unloading processes, as well as the sorting procedures, are now perfectly documented and traceable at any time," says CEO Wolfgang P. Albeck .

Trans-o-flex employees now only need between five and ten minutes to investigate the few outliers on a daily basis. "Compared to our other locations without automated package tracking, this represents a time saving of over 95 percent," notes Albeck, who, together with the works council, has appointed a five-person team to operate ParcelVIS.

The works council was informed about every step during the project phase. "In a kick-off meeting, practical examples were used to clarify that this is a video management system and not video surveillance," Albeck notes. All participants "immediately recognized that ParcelVIS significantly increases our productivity and avoids unnecessary search efforts."