WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Car wash with accelerator

September 24, 2025

Conveyor technology provider Frei is celebrating the modernization and expansion of the container conveyor system at the Migros Cooperative in Lucerne – with a focus on performance, automation, and future-proofing. The new conveyor lines can handle up to 2,400 containers per hour.

Exyz in the high-bay warehouse

September 24, 2025

Zambelli, a provider of solutions for building envelopes, shelving, industrial metalworking, and heating technology, is also one of the leading manufacturers of roof drainage systems. Here alone, the product range includes 17,500 items. A clear case for SSI Schäfer in the new logistics center in Grafenau.

Again powerful in a double pack

September 23, 2025

which was held jointly with the packaging trade fair "Empack" in Zurich in early 2025 will reopen its doors in Bern on January 28 and 29, 2026. Last January, over 4,000 visitors attended.

Efficient handling

September 23, 2025

Under the Kion umbrella, Baoli stands for solid and robust industrial trucks at competitive prices. The new KBP 14H, a low-lift pallet truck with a lithium-ion battery, also makes in-house material handling simple and straightforward.

Transport world at Bernexpo

September 22, 2025

Only a few weeks remain until transport.ch 2025. From November 5 to 8, the most important Swiss event for light and heavy commercial vehicles, mechanical and body workshops once again be present with 240 exhibitors and over 800 brands on almost 40,000 m² of space in ten halls.

Review for thought leaders

September 22, 2025

The 350 participants of the Fraunhofer IML Future Congress in Dortmund received prominent input on topics ranging from simplifying material flows using AI to ideas for space logistics. Among them was Gilgen Logistics, where innovation is a declared driver of business activities.

Google Street View in the warehouse

September 21, 2025

"We already have a wide range of assistance systems, cameras, and sensors in use," explained Rolf Huber at forklift manufacturer Still's Innovation Day in front of an audience of experts, customers, and visitors in Otelfingen. Now, an AI is perfecting the whole thing. With new LiDAR scanners and preferably in real time.

The clever fox at Dachser

September 19, 2025

Stefan Hohm, Head of Development at Dachser, was " Logistics Leader of the Year 2025 " politics, and academia . He was honored primarily for the @ILO project, a highly efficient digital twin for packages, assets, and processes in general cargo warehouses.

“Millionaires” in the deep-water port

September 19, 2025

Gebrüder Weiss is currently celebrating an "anniversary container" at Germany's only deep-water port, Wilhelmshaven. Together with the local terminal operator Eurogate and Hapag-Lloyd, the millionth sea freight container (TEU) of 2025 was handled.

1100 young professionals at the start

September 16, 2025

Starting today, around 1,100 talented young professionals from all language regions of Switzerland will demonstrate their professionalism in more than 90 professions at the SwissSkills competition in Bern The Swiss Association for Vocational Training in Logistics, Swiss Logistics by ASFL SVBL, will also be participating

Reduce energy losses

WAGNER Switzerland AG

Reduce energy losses

August 30, 2022

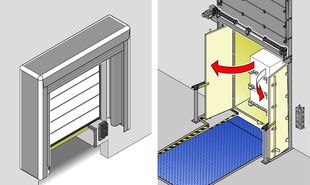

For loading and unloading operations in temperature-controlled warehouses, we recommend a front combined with a fixed insulation panel below the loading bridge. An HTL2 ISO, as offered by Hörmann, is particularly worthwhile for loading and unloading operations lasting eight to nine hours per day.

The energy-saving HTL2 ISO lip-type loading bridge, combined with a customized sectional door, is specifically designed for this application. It offers approximately 55 percent better thermal insulation than non-insulated lip-type loading bridges, both in the rest position and during loading, helping to save energy costs.

The loading bridge features 50 mm thick, moving insulation panels mounted beneath the platform and the lip, almost at the same height as the insulation of the hall floor. This patented solution reduces energy losses through the structure (transmission losses) and ensures efficient thermal insulation. When the lip is extended, an insulation panel is moved along, thus reducing energy losses during loading. Ventilation heat loss, for example, through the gap between the loading bridge and the pit, is also reduced by vertical and horizontal seals.

All images: Hoermann

All images: Hoermann

The IC (Increased Clearance) type lip has a 390 mm long free support as standard and is therefore also suitable for refrigerated vehicles with a rear-sloping loading floor.

The HTL2 ISO is much quicker to install, as all insulation panels and seals are pre-assembled. Furthermore, the HTL2 ISO is easy to maintain thanks to its easily accessible hydraulic system.

For new buildings, Hörmann recommends combining the HTL2 ISO with a matching industrial sectional door that is tapered in the lower section to match the contours of the loading ramp.

In conjunction with the HTL2 ISO, the sectional door closes directly onto the 160 mm protruding insulation panel of the loading bridge, ensuring optimal thermal insulation even when not in use. The sealing and centering unit developed by Hörmann reliably guides the door near the loading ramp and ensures optimal sealing. Thanks to the modified design in the lower part of the door, only a small recess (110 mm wide) is required in the pit for the door guide.

The HTL2 ISO is also available in conjunction with the DOBO (docking before opening) system. The truck can dock at the loading bay with its doors closed. The vehicle doors are only opened once the sectional door has been raised for loading or unloading.