WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

RBG squadron at the Bosporus

October 31, 2025

TGW Logistics has announced an order for an automated small parts warehouse on the outskirts of Istanbul for Ekol Lojistik. The Turkish 3PL provider will use more than one hundred Mustang E+ stacker cranes on three levels to handle the storage and retrieval of retail and e-commerce orders.

"Omniverse" in the "Middle Kingdom"

October 31, 2025

As this year's CeMAT Asia Shanghai demonstrated, European technology remains a crucial factor for markets in the Far East. The Kion Group, with its AI and NVIDIA products, was once again in high demand at the three-day event, organized by Deutsche Messe (Hanover) in cooperation with partners .

Toni Gabriel is moving to TGW

October 30, 2025

“New job, new adventure!” says Toni Gabriel, who has just announced his new position as Sales Project Manager at the systems integrator TGW in Rotkreuz. He was impressed by the Austrian company TGW's combination of innovation, team spirit, and smart, future-oriented logistics solutions.

Pallets «unchained»

October 30, 2025

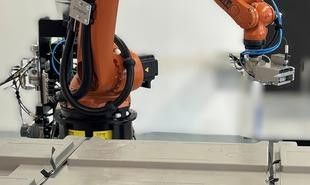

A system called "PolyCut" removes strapping from pallets, thus replacing time-consuming and ergonomically demanding manual work steps. It can be used as a stand-alone solution or integrated into existing handling systems and their controls or warehouse management systems.

High destructive potential

October 30, 2025

As feared, the US tariffs are causing a collapse in tech exports. According to Swissmem, the resulting negative effects took full effect within seven weeks in the third quarter. Exports from the Swiss tech industry to the US plummeted by 14.2% compared to the same quarter of the previous year .

Swiss Logistics Campus in Zofingen officially opened

October 29, 2025

Numerous visitors, friends and the entire crew of the new Swiss Logistics Campus of the Swiss Association for Vocational Training in Logistics, Swiss Logistics by SVBL ASFL, found their way to the official opening of the impressive new location in Zofingen over the weekend.

Leading in intralogistics with robots

October 29, 2025

the International Federation of Robotics' (IFR) annual report "World Robotics 2025 - Service Robots," approximately 102,900 robots for transport and logistics tasks were sold worldwide in 2024. Sales increased by 14 percent in 2024. More than three-quarters came from Asia, and 11 percent from Europe.

"Organic" combined with high tech

October 29, 2025

High-tech and products processed from natural ingredients are not mutually exclusive. "Organic" does n't mean everything is done manually, but rather that it adheres to high ecological standards. This is also true for the organic wholesaler Weiling, where an AutoStore system has recently enabled peak logistical performance.

Ready for the "Great Leap"

October 28, 2025

Founded in Xuzhou in 1943, the Xuzhou Construction Machinery Group (XCMG) generates approximately €13 billion in revenue with 13,000 employees worldwide. Its portfolio includes construction machinery, cranes, commercial vehicles, and a growing range of material handling equipment and port handling machinery.

Completely unmanned logistics?

October 28, 2025

Warehouse robotics specialist Geekplus is launching its new picking station "Geek+ Brain," ushering in a new era of warehouses operating entirely without human workers. CEO Yong Zheng " a major step from partial automation to full process intelligence . "

Parking garage as a storage system variant

WAGNER Switzerland AG

Parking garage as a storage system variant

June 15, 2022

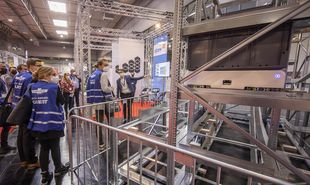

The hit list of IFOY nominees: Robotized, cube-shaped warehouse systems are in high season. e.scala is a highly standardized goods-to-person system that uses a single robot to replace all the traditional components of an automated warehouse and can be installed in just three months.

The e.scala is a robot-based storage and picking system. The robot moves in three dimensions within a storage cube and easily reaches any point in a warehouse or production area via a rail system. A patented ramp system allows the robots to move from storage level to storage level and overcome height differences outside the storage cube. The high level of flexibility allows virtually any customer requirement to be met using standard modules.

During the IFOY test days in Dortmund, the ramp assembly was lifted into the test hall in one piece. The only moving part is the rail-mounted shuttle, which stow calls "Robot"—it couldn't be simpler. Otherwise, the customer gets pure redundancy. The strength of e.scala lies in its relatively straightforward entry into automation.

One of its unique selling points is that the entire system consists of only 15 different parts. However, only the "exciting" warehouse pre-zone with three lines for accessing four levels in the warehouse was demonstrated at the test camp. How the system works is also reflected in the product name: The "e" comes from escalator. The term "scala" is intended to demonstrate scalability. The entire installation requires no vertical lift, i.e., no elevator. The individual aisles are accessed via inclined ramps, which significantly reduces the risk of errors. The "connector" is the section where the robot can change direction in order to move the goods to be transported into or out of the warehouse and, with or without transported goods, to change levels.

Photo: IFOY / Schütze

Photo: IFOY / Schütze

In principle, as the auditors in the IFOY audit also determined, the system is similar to a parking garage, although the actual order system is usually located outside the warehouse. The manufacturer also places great importance on the system's redundancy: According to the manufacturer, the only thing that could break is the robot. However, it doesn't then block the entire system.

The transport robot has eight wheels: four for travel in the X direction, while the other four move the robot in the Y direction after the wheel change. The entire structure essentially only requires two power sources: once for the charging station, where the individual robots can charge their power packs—with a charging time of eight seconds, they can travel for about twelve minutes—and once for Wi-Fi robot communication with the warehouse management system. This also means that no cables are installed in the entire pre-zone.

The individual modules of the e.scala system are designed to measure 5.0 meters x 2.5 meters and are scalable. The system can easily accommodate a total height of 24 meters. Stow Traffic Control (STC) detects when the robot passes over the installed passive RFID tags in the respective section of the route.

Because the system is highly standardized, it can easily meet even small requirements, starting with 500 storage locations to be automated. Because the system's 15 basic components and the robot can be delivered directly from stock, an entire system can be planned and implemented within a very short time. Even in the event of a robot failure, the system's availability is exceptionally high, as access to every location in the system is guaranteed at all times via multiple paths.

Because low initial investments and easy scalability later on are crucial for automating smaller systems, e.scala seems to be ideal for SMEs that don't want to go all out with their investment in automated intralogistics right away.

The actual IFOY award winners will remain secret until the very end. The IFOY gala and awards ceremony will take place on June 30 at BMW Welt in Munich.