WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Not «breath-» but wireless

October 9, 2025

Bluepath Robotics, an internal innovation project at the Ford subsidiary Otosan, which was spun off at the end of 2023, develops and produces autonomous mobile robots for a wide range of intralogistics applications. Now, Wiferion enables the inductive power supply of the AMRs.

Electric monorail system for Quark & Co

October 9, 2025

NÖM produces a wide range of dairy products, yogurt, butter, and curd cheese from approximately 450 million kg of milk from 2,200 farmers in the region build a fully automated shipping warehouse with comprehensive conveyor technology for 26,000 pallet spaces.

The fire is left without air

October 8, 2025

The fire protection specialists of the Wagner Group have been honored with the "GIT Safety Award 2026" for their "OxyReduct F-Line." The system expands the OxyReduct process with H2- based fuel cell technology, which simultaneously ensures emission-free energy supply.

Temperature-controlled at the motorway junction

October 7, 2025

Movianto, a logistics service provider specializing in pharmaceuticals and healthcare, is setting up a new cold storage facility in Wiesloch-Walldorf this month. A photovoltaic system there produces approximately 3,100 MWh per year, more electricity than the site consumes.

Fusion reactor in creep mode

October 7, 2025

Despite all the political turmoil currently shaking the world, work on the ITER fusion reactor, in which countless nations are involved, continues – much like on the ISS. Recently, another of the 15-meter-high segments for the future plasma chamber was delivered by heavy-duty transport.

Nonstop strapping

October 6, 2025

Mosca offers a comprehensive portfolio of integrated end-of-line systems for transport packaging, strapping machines, stretch wrappers, and associated consumables. Strapping made from materials such as PP and PET is produced with increasing recycled content.

Dynamic open-plan area

October 6, 2025

Relocations often involve considerable effort. Furniture needs to be transported, boxes packed, and unwanted items disposed of. The company " Optimal Umzug " from Lachen, Canton of Schwyz, offers services tailored to the greater Zurich area.

Optio L-Series updated

October 6, 2025

Developed with the user in mind, the completely redesigned generation of low-level order pickers in the Optio L series from TMHE sets new standards. Increased platform lifting heights, low entry, and versatile model variants for loads up to 2.5 t make these devices highly sought-after helpers.

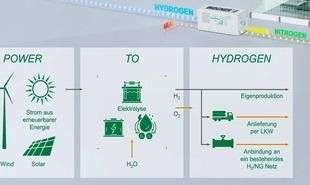

Cold chain in transition: Ambitious goals

October 2, 2025

Temperature-controlled logistics is facing an energy revolution: battery-electric trucks, long-range hydrogen vehicles, and cryogenic cooling with nitrogen are transforming the industry. Enough "material" for the SVTL to discuss future processes and alternatives at Galliker in Altishofen.

DLR expands drone defense

October 2, 2025

While Russian drones have long been surveying German bases and critical infrastructures as potential targets for their “ asymmetric warfare ” a project called CUSTODIAN (Counter-UAS Technologies for Detection, Interception and Neutralization) is now slowly gaining momentum at the DLR.

State-of-the-art conveyor technology

WAGNER Switzerland AG

State-of-the-art conveyor technology

June 28, 2022

Updated conveyor technology methods are designed to increase efficiency at SSI Schäfer. For example, the speed of the motorized rollers adapts to the current throughput (speed on demand) . The control system, electronics, and maintenance strategy meet the modern requirements of Industry 4.0 .

SSI Schäfer has further developed its carton and container conveyor technology, significantly increasing energy efficiency and system availability. Proven technologies have been refined and simultaneously incorporated into a modern design. Modern conveyor technology must simplify processes, enable smooth material flows, and supply the various warehouse areas with the right goods efficiently and in a timely manner. It should sort, transfer, store, and accumulate load carriers.

According to the manufacturer, the new carton and container conveyor system is suitable for small load carriers up to 50 kg, such as containers, cartons, trays, and polybags, which can be transported on the conveyor system not only in single types but also in mixed quantities. Thanks to an intelligent and modular design, the coordinated conveyor system components can be individually combined, providing customers with a highly flexible and scalable overall system. It can even be used in a deep-freeze environment down to -28°C.

SSI Schäfer boasts more than 15 years of experience and expertise in the field of conveyor technology and a multitude of successful projects, in which over 1,000 km of conveyor technology have been sold and installed to date. In times of climate change, topics such as sustainability and energy conservation are becoming increasingly important. "The latest generation of carton and container conveyor technology from SSI Schäfer therefore consumes significantly less energy than before – while simultaneously increasing throughput," says Product Manager Christian Steiner. "This is made possible by CAN bus technology, smart control, and 48-volt drive technology. Due to smaller cable cross-sections and longer cable lengths, there is less line loss for the same performance, as well as increased energy efficiency thanks to larger and more efficient power supplies."

According to the company, the increased hardware performance, the new control system, and the intelligent combination of components lead to a throughput increase of up to 30%. Thanks to the slimmer roller design and the resulting savings in plastic, SSI also avoids approximately 31 tons of CO2 emissions per year. The Speed on Demand function, which allows the speed of the motorized rollers to be adjusted to the current throughput, will contribute to increased energy efficiency in the future.

A new control unit for controlling the motorized rollers, combined with CAN bus technology, provides the basis for networked data exchange between the systems and thus for a predictive maintenance strategy. "By collecting, analyzing, and evaluating system-specific data in the SSI CMMS (Computerized Maintenance Management System), it will be possible to predict individually defined maintenance intervals in real time," says Steiner.

Photos: SSI Schäfer

Photos: SSI Schäfer

In combination with the control software, the system functions can be extensively parameterized, even during operation. Thanks to visualization with the Lighthouse version of the WAMAS warehouse management system, warehouse data is made transparent and visible in real time. A central standard interface connects both the new carton and container conveyor technology and all other conveyor systems in the warehouse with the MFS material flow system.

High-quality components ensure a long service life. The new motor roller features a robust, break-resistant roller design, and the lifting carriage of the belt pusher features an increased robust kinematic construction. The new conveyor technology also features roller conveyor finger guards and reduced noise emissions thanks to the use of pneumatic-free technology. A standardized plug-and-play connector system and streamlined cabling simplify installation and maintenance.

The system, says SSI Schäfer after the considerable innovation effort, "utilizes the potential of digitalization and is optimally aligned to Industry 4.0 and the requirements of the future."