WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

Not «breath-» but wireless

October 9, 2025

Bluepath Robotics, an internal innovation project at the Ford subsidiary Otosan, which was spun off at the end of 2023, develops and produces autonomous mobile robots for a wide range of intralogistics applications. Now, Wiferion enables the inductive power supply of the AMRs.

Electric monorail system for Quark & Co

October 9, 2025

NÖM produces a wide range of dairy products, yogurt, butter, and curd cheese from approximately 450 million kg of milk from 2,200 farmers in the region build a fully automated shipping warehouse with comprehensive conveyor technology for 26,000 pallet spaces.

The fire is left without air

October 8, 2025

The fire protection specialists of the Wagner Group have been honored with the "GIT Safety Award 2026" for their "OxyReduct F-Line." The system expands the OxyReduct process with H2- based fuel cell technology, which simultaneously ensures emission-free energy supply.

Temperature-controlled at the motorway junction

October 7, 2025

Movianto, a logistics service provider specializing in pharmaceuticals and healthcare, is setting up a new cold storage facility in Wiesloch-Walldorf this month. A photovoltaic system there produces approximately 3,100 MWh per year, more electricity than the site consumes.

Fusion reactor in creep mode

October 7, 2025

Despite all the political turmoil currently shaking the world, work on the ITER fusion reactor, in which countless nations are involved, continues – much like on the ISS. Recently, another of the 15-meter-high segments for the future plasma chamber was delivered by heavy-duty transport.

Nonstop strapping

October 6, 2025

Mosca offers a comprehensive portfolio of integrated end-of-line systems for transport packaging, strapping machines, stretch wrappers, and associated consumables. Strapping made from materials such as PP and PET is produced with increasing recycled content.

Dynamic open-plan area

October 6, 2025

Relocations often involve considerable effort. Furniture needs to be transported, boxes packed, and unwanted items disposed of. The company " Optimal Umzug " from Lachen, Canton of Schwyz, offers services tailored to the greater Zurich area.

Optio L-Series updated

October 6, 2025

Developed with the user in mind, the completely redesigned generation of low-level order pickers in the Optio L series from TMHE sets new standards. Increased platform lifting heights, low entry, and versatile model variants for loads up to 2.5 t make these devices highly sought-after helpers.

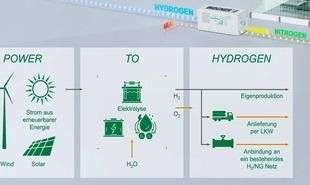

Cold chain in transition: Ambitious goals

October 2, 2025

Temperature-controlled logistics is facing an energy revolution: battery-electric trucks, long-range hydrogen vehicles, and cryogenic cooling with nitrogen are transforming the industry. Enough "material" for the SVTL to discuss future processes and alternatives at Galliker in Altishofen.

DLR expands drone defense

October 2, 2025

While Russian drones have long been surveying German bases and critical infrastructures as potential targets for their “ asymmetric warfare ” a project called CUSTODIAN (Counter-UAS Technologies for Detection, Interception and Neutralization) is now slowly gaining momentum at the DLR.

Revelation at the saw

WAGNER Switzerland AG

Revelation at the saw

June 27, 2022

Thomas Graham & Sons, a family-run steel merchant in Carlisle near the Scottish border since 1892 offers a range of approximately 2,000 tons of various materials as well as add-ons such as galvanizing, laser cutting, and sawing . A win A 4.6 expands its capacity.

purchasing the additional sawing machine, British steel merchant Thomas Graham & Sons chose the fully automatic band saw from the Rhine Valley. Its suitability for a wide range of tasks. From tools and workwear to welding equipment and accessories to steel and metal products: Thomas Graham & Sons is a broadly positioned partner to industrial and trade businesses – and thus extremely successful. The company now employs more than 200 people.

The processing spectrum and the company's own machinery fleet have grown continuously over the years. More and more customers are taking advantage of these additional services – including a manufacturer of trucks for the forestry industry: In 2018, Thomas Graham & Sons received an order from the company to cut flat steel pieces from alloyed structural steel for the production of chain links – at a rate of 350 tons per year.

The alloy has a particularly high boron content to increase hardness during heat treatment. "This material can be machined easily with a standard bimetal saw blade. However, our capacity simply wasn't sufficient for this quantity," recalls Operations Manager Phil Barnes, who has been with the company for 17 years.

The company was already using ten saws from three different manufacturers – but decided to go with Kasto for a fourth. "We initially compared various options and asked the potential suppliers to process a sample batch of our boron steel," reports Phil Barnes. Kasto then invited the managers to a live machine demonstration on-site. The sawing technology specialist, headquartered in Achern, southern Germany, has had a branch in Milton Keynes, UK, for many years. At the center of the test cut: the A 4.6 fully automatic band saw.

Quality at an attractive price

The Kastowin is suitable for various steels, making it a flexible solution. Extensive standard equipment makes the saw particularly efficient. A high proportion of common parts within the series also ensures that Kasto can offer the new saws at a significantly lower price than comparable products from other manufacturers. This does not detract from the quality of the machine, which is manufactured entirely in Germany: The torsion-resistant upper section offers high vibration damping, and housing components made of robust steel ensure smooth operation. The saw achieves a cutting accuracy of +/-0.1 mm per 100 millimeters of cutting length – at cutting speeds of up to 150 m/min.

For the truck manufacturer, the company saws bundles of 24 bars with a cross-section of 50 x 20 mm and two beveled edges into 280 mm long pieces. Each cycle comprises ten cuts and produces 240 individual parts. "The performance of the Kastowin far exceeded our expectations," Barnes explains. "We assumed each cutting cycle would take eight hours – in fact, it was completed in just 3.5 hours."

Higher feed

The Kastorespond system, developed specifically for this series, proves particularly advantageous. It continuously monitors the forces on the saw blade and intelligently converts them into feed movements. This enables a higher blade feed rate while ensuring excellent cutting quality. "Furthermore, the Kastowin can automatically start the trimming cut when a new bundle is inserted," adds Phil Barnes. "Other machines must first cut the bundle to level the end face before the bar can be measured." This alone saves Thomas Graham & Sons ten minutes per cutting cycle.

Photos: A1 / Kasto

Photos: A1 / Kasto

The Kastowin also scores highly in terms of accuracy. "The machine easily maintains the required tolerance of plus/minus one millimeter," Barnes praises. With the new fully automatic band saw, the steel merchant sees itself well positioned for the future. "We have a growing customer base, more than half of whom require cut material. Therefore, band sawing is an important process step for us," explains Operations Manager Phil Barnes. "The Kastowin is a true revelation in terms of productivity and cutting accuracy."