WWW.LOGISTICSINNOVATION.ORG

The online magazine for Switzerland, the EU and the rest of the world

The fire is left without air

October 8, 2025

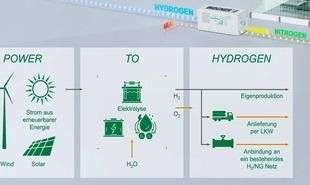

The fire protection specialists of the Wagner Group have been honored with the "GIT Safety Award 2026" for their "OxyReduct F-Line." The system expands the OxyReduct process with H2- based fuel cell technology, which simultaneously ensures emission-free energy supply.

Temperature-controlled at the motorway junction

October 7, 2025

Movianto, a logistics service provider specializing in pharmaceuticals and healthcare, is setting up a new cold storage facility in Wiesloch-Walldorf this month. A photovoltaic system there produces approximately 3,100 MWh per year, more electricity than the site consumes.

Fusion reactor in creep mode

October 7, 2025

Despite all the political turmoil currently shaking the world, work on the ITER fusion reactor, in which countless nations are involved, continues – much like on the ISS. Recently, another of the 15-meter-high segments for the future plasma chamber was delivered by heavy-duty transport.

Nonstop strapping

October 6, 2025

Mosca offers a comprehensive portfolio of integrated end-of-line systems for transport packaging, strapping machines, stretch wrappers, and associated consumables. Strapping made from materials such as PP and PET is produced with increasing recycled content.

Dynamic open-plan area

October 6, 2025

Relocations often involve considerable effort. Furniture needs to be transported, boxes packed, and unwanted items disposed of. The company " Optimal Umzug " from Lachen, Canton of Schwyz, offers services tailored to the greater Zurich area.

Optio L-Series updated

October 6, 2025

Developed with the user in mind, the completely redesigned generation of low-level order pickers in the Optio L series from TMHE sets new standards. Increased platform lifting heights, low entry, and versatile model variants for loads up to 2.5 t make these devices highly sought-after helpers.

Cold chain in transition: Ambitious goals

October 2, 2025

Temperature-controlled logistics is facing an energy revolution: battery-electric trucks, long-range hydrogen vehicles, and cryogenic cooling with nitrogen are transforming the industry. Enough "material" for the SVTL to discuss future processes and alternatives at Galliker in Altishofen.

DLR expands drone defense

October 2, 2025

While Russian drones have long been surveying German bases and critical infrastructures as potential targets for their “ asymmetric warfare ” a project called CUSTODIAN (Counter-UAS Technologies for Detection, Interception and Neutralization) is now slowly gaining momentum at the DLR.

ASTAG and GS1 to go green together

October 1, 2025

The Swiss Commercial Vehicle Association and GS1 Switzerland are merging their "Lean & Green" and "We go green!" initiatives. Both ASTAG and GS1 are embracing sustainability as a triad of economy, society, and the environment.

Interoperability proven

October 1, 2025

At an " Automation Day " hosted by Agilox, insights into the current status and future direction of the robotics provider were provided, rounded off by workflows that – modeled on real practical processes – demonstrated interoperability with the AMRs together with a Fanuc robot arm and a Palomat.

Timing belt instead of rope technology

WAGNER Switzerland AG

Timing belt instead of rope technology

April 29, 2022

At LogiMAT from May 31 to June 2, Continental will showcase an Autonomous Mobile Robot (AMR) for material flow in production plants, warehouses, and logistics centers. The technology provider offers high-performance timing belts for high-bay warehouses and its tire portfolio for forklifts.

The Autonomous Mobile Robot is equipped with proven technologies: Lidar sensors for 360-degree detection of its surroundings, 3D camera systems, intelligent software, and an optional ultra-wideband transmitter for precise live tracking of the AMR within a fleet make the robot vehicle a valuable asset. It independently carries out transport tasks, can avoid obstacles, and calculate alternative routes. An optional fleet management system can coordinate a larger fleet of AMRs.

Continental initially designed the autonomous vehicle for its own benefit: Engineers at the technology company couldn't find a suitable solution on the market to make material flow and handling of heavy product components more efficient in its own factories. "We have developed a customized robotics solution that is currently being very successfully integrated into everyday production at our hydraulic brake systems factories in Slovakia and China. The intelligent transport robot is scheduled to go into series production for external customers this year," said Pierre Pomper, Head of Autonomous Mobile Robots at Continental.

High-performance timing belts

High-bay warehouses are at the heart of many logistics processes. Effectively loading and unloading them is a major challenge, one that is increasingly being handled by belt-driven storage and retrieval machines. As a core element of intralogistics processes, they position goods quickly and precisely. Continental, together with partners, has developed a new drive technology based on the pulley principle and operates with a redirected belt drive. A Synchrodrive timing belt offers several advantages over the commonly used rope technology: minimized wear, reduced maintenance, shorter positioning times, and longer replacement intervals. This belt technology requires no lubrication and has proven itself in series production – with heavy loads as well as in deep-freeze applications at temperatures as low as minus 30 degrees Celsius. Continental can manufacture the compounds required to produce the corresponding belts in-house.

Tires for logistics

Whether transporting heavy loads, covering longer distances, or using automated vehicles for material handling, Continental will be showcasing its current tire portfolio for the logistics and port industries and its digital solutions for more efficient tire use at LogiMAT 2022. Driven by the pandemic, hygiene regulations in the pharmaceutical and food industries, as well as in a variety of other industries, have increased significantly. Continental is meeting these requirements with its Clean Tires, which it will also be showcasing at the trade fair. Driving and braking marks should be minimized as much as possible, especially in highly hygienic production conditions. Tires like the SC20, CS20, and CSEasy Clean versions thus visibly contribute to a cleaner and more hygienic working environment.

www.continental.com